Immersive technologies for industry are now a key driver of innovation. Groupe Atlantic, a leading European manufacturer of thermal and sanitary equipment, places innovation at the heart of its priorities.

So, to address the daily challenges of competitiveness and efficiency faced by industries, the company decided to integrated SKYREAL’s immersive technologies, specially designed for industry.

Since then, the use of virtual reality has become a key tool, from research and development to operator training, from production line optimization to sales initiatives.

Examples of industrial uses of virtual reality at Groupe Atlantic

Within Groupe Atlantic, virtual reality is applied across various fields to meet the needs of different business areas. Here are some examples:

- Research & Development and Design Offices: Product analysis, assembly feasibility, and maintainability studies, optimization of assembly sequences.

- Processes, Methods, and Industrialization: Production tool layout, line organization, and workstation ergonomics.

- Production and Maintenance: Simulations for operator training, equipment analysis before disassembly.

- Quality, Safety, and Environment (QSE): Industrial safety assessments, improvement of working conditions.

- Logistics and Transport: Optimization of supply chains and material flows.

- Sales and Marketing: Product presentations and virtual tours to engage prospects and clients.

A transformation driven by digital innovation

Under the leadership of Yves David, IT Engineering Product Manager within the IT Department, Groupe Atlantic has orchestrated this transformation in close collaboration with the R&D and Methods teams. The IT Department’s central role in implementing immersive solutions highlights the company’s strong commitment to improving productivity, reducing costs, and fostering cross-functional collaboration.

The decision to adopt SKYREAL followed an in-depth benchmark study, during which SKYREAL stood out for its advanced features, integration with Unreal Engine, and ability to meet Groupe Atlantic’s specific needs, including:

- The ability to record changes made in VR directly into CAD (Back To CAD feature), including: designs (pipes, cables, space allocations), tickets, positions, colors, visibility of components.

- Ergonomic studies for workstations.

- The ability to create immersive training modules based on CAD data.

- An open software platform allowing for easy creation and integration of extensions.

- Ease of use and quick adoption.

As a result, numerous Groupe Atlantic employees have become regular users of immersive technologies, and within just a few months, SKYREAL has been deployed across multiple sites.

Immersive solutions for industry that deliver concrete, measurable results

Users quickly reported tangible results from their use of immersive solutions. Here are four key highlights:

- €80,000 saved by detecting errors early in a site reorganization project.

- 50–70% reduction in prototyping needs.

- Shortened product development timelines.

- Efficient training for teams without disrupting production lines.

To illustrate the impact of immersive technologies within the company, here are two concrete use cases that illustrate the penetration of immersive technologies in the Atlantic Group with clear returns on investment:

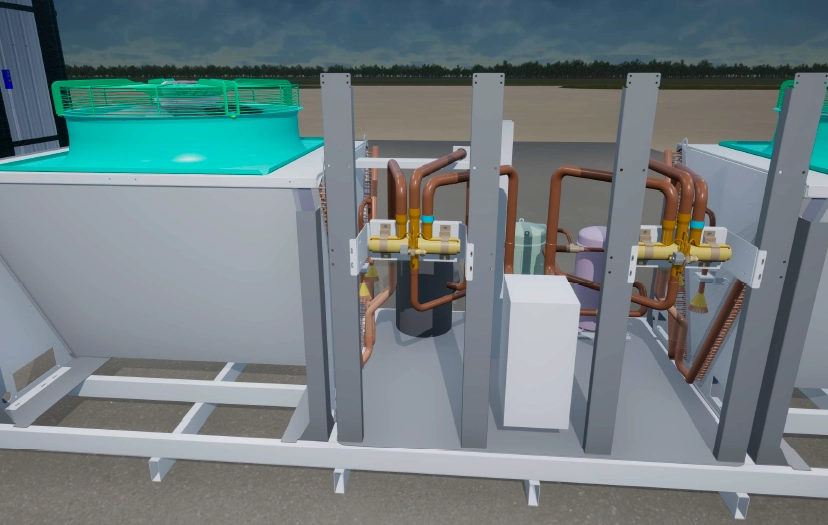

1. Use Case: Heat pump design

A flagship product of Groupe Atlantic, the heat pump exemplifies the strategic value of VR in industrial product design.

From the early R&D phase, engineers used SKYREAL to simulate component assembly feasibility and accessibility. This allowed them to identify areas for improvement early and avoid costly design errors later in development.

(See also this use case of VR for accessibility with eXcent)

Moreover, by “stepping into the shoes” of operators through immersive simulations, they designed a product better suited to real-world constraints — one that is faster and easier to assemble.

The financial impact was also significant: traditionally, four physical prototypes, costing €20,000 each, were required. Thanks to VR, this number was halved, resulting in substantial savings and a faster development process.

Additionally, immersive simulations effectively prepared operator training, enabling a quick skills ramp-up and significant time savings.

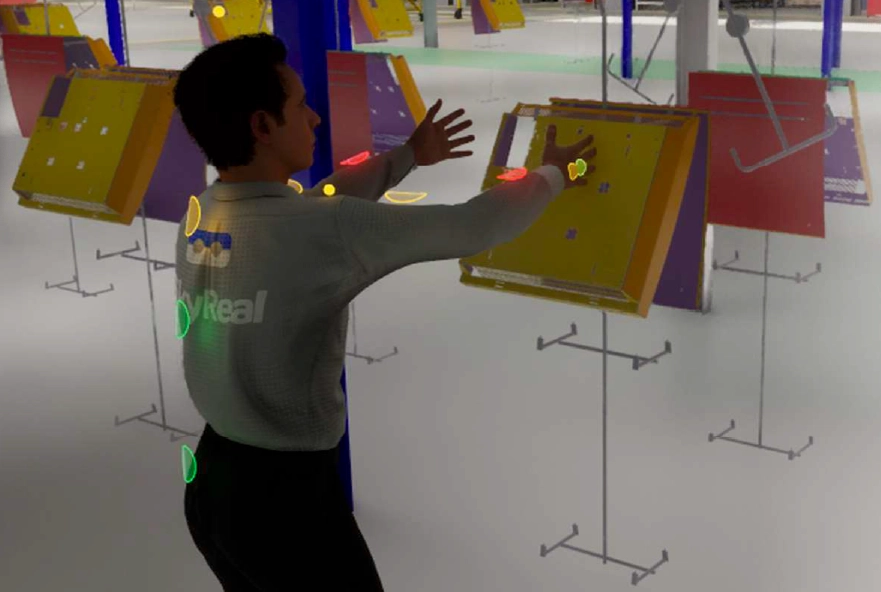

2. Use Case : Optimization of a paint line

At Groupe Atlantic’s La Roche-sur-Yon plant, SKYREAL’s solutions were used to improve the design of a new paint line.

By simulating multiple layout scenarios, teams identified the optimal configuration before any physical changes were made, reducing costs and minimizing production interruptions. Ergonomic studies then helped refine workstation setups to maximize efficiency and reduce operator strain.

Training also benefited from this approach: operators trained on a virtual version of the line, eliminating the cost, time, and safety constraints of real-world training.

Ultimately, virtual reality has proven to be a true ally in manufacturing, offering tailored solutions to modern industry challenges and boosting competitiveness.

A forward-looking collaboration

The deployment of SKYREAL has not only enhanced Groupe Atlantic’s productivity but also strengthened its position as an innovation leader in the thermal equipment sector.

Virtual reality is now a strategic tool for transforming work methods and tackling the industrial challenges of the future.

With SKYREAL, Groupe Atlantic demonstrates that integrating VR into industrial processes accelerates innovation while optimizing costs and timelines. This collaboration paves the way for broader adoption of immersive technologies, reshaping the industry of tomorrow.