Virtual reality (VR) makes manufacturing processes much easier. It represents an undeniable advantage for saving time, money and improving teamwork. Every stage of production can benefit from the use of immersive technologies, from production to the customer experience.

In this race against time, where companies need to be ever more productive, new tools like VR have become essential. Today, to stay competitive, you need to know, understand and anticipate these technologies.

How VR is used in industrial production ?

The use of virtual reality brings benefits at every stage of an industrial production project.

In many cases, the technology saves considerable time. In other cases, customers gain confidence and teams gain skills.

At SkyReal, we have designed a solution that virtualizes every phase of an industrial project. Our customer, Groupe ADF, a specialist in industrial equipment, shares its best practices for turning VR production into an asset.

Manufacturing in virtual reality : Presales

The pre-sales phase is crucial to the success of a project. The most important thing is to have a final rendering that meets the customer’s needs and expectations.

Presenting an idea is no longer limited to words or sketches on paper. In the age of Industry 5.0, the 3D materialization of projects has become a crucial step in bringing a vision to life. For innovation projects in particular, 3D visualization offers invaluable advantages that can greatly influence the pre-sales phase.

During this stage, new technologies can save precious time, as they can help to convince by making concrete a project that until then was embryonic. Thanks to a virtual reality headset, customers can be immersed directly in their project. All parties involved can build the concept together and validate precise elements (size, location, ergonomics).

Both customer and manufacturer are reassured and confident. This saves a considerable amount of time during implementation, since all the parties involved agree before production starts.

Design using virtual reality

The design phase is essential, as it determines the final product. If a mistake is made during this stage, the whole project can be compromised and fall behind schedule. Using virtual reality for design means that any errors can be detected earlier and as they occur.

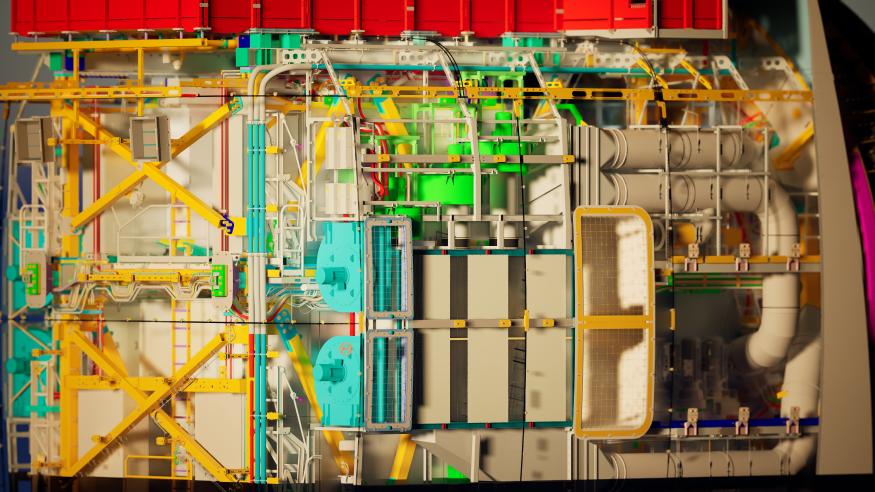

This crucial stage of the project involves the construction and validation by all stakeholders of the precise elements (size, location, ergonomics) making up the production line before commissioning.

Thanks to 3D immersion, engineers can check the accessibility, ergonomics and maintainability of equipment. When the project is delivered, it is operational quicker, because problems have been identified before commissioning. The benefits are real, both in terms of time and performance: thanks to VR, there is an increase in productivity.

Commissioning

Commissioning is one of the last stages of an industrial project before delivery. It consists in making the final configurations and procedures before the operating phase.

During this stage, virtual reality can be used to train operators on the equipment. As a result, teams are operational more quickly and their skill levels increase. As in the previous phase, the use of VR helps to increase the production rate of the tools: we know better, so we produce more efficiently.

It is also at this stage that virtual commissioning concepts can be applied, ensuring that all the operational elements of a project function as they should. This quality approach can now be achieved in VR thanks to SkyReal.

Manufacturing in virtual reality simplify the exploitation phase

For an industrial product to work successfully, it has to be understood by operators.

Virtual reality offers the advantage of integrating operational teams into the knowledge of their future equipment. In a virtual environment, they are confronted with the problems they are already familiar with, so that they can familiarize themselves with the new tools. This ensures that the equipment is adapted to existing skills, thus ensuring the long-term durability of the industrial installation.

Digital twin: towards an upsurge in industrial production?

Technologies are always moving fast, and the business sectors that use them are likely to evolve rapidly too.

Industry has always been able to take advantage of technological advances, and on numerous occasions has brought about profound changes. Today, Industry 5.0 dominates: intelligent machines cooperating with humans. The role of technology in the manufacturing sector has never been greater.

The digital twin or virtual twin, is just one example of this transformation. In 2023, virtual reality will benefit from other technological advances. The digital twin has already proved its worth on numerous occasions in industry, particularly in maintenance.

In production, too, digital twin has proven its efficiency and speed. Coupled with virtual reality, this technology is becoming a must-have for the industrial sector.

Today, the digital twin is profoundly transforming industry and manufacturing. Compared with virtual reality, this technology offers valuable new features for industrial product commissioning: simulations with real-time data feedback.

It means it’s possible to test configurations and see their potential and efficiency in real time. This is a real game-changer during the design and commissioning phases, avoiding time-consuming and costly mistakes and backtracking. Today, digital twins offer a wide range of possibilities for the industrial sector.

New technologies such as virtual reality and the digital twin should no longer be ignored by manufacturers. Having outgrown the gadget phase, they are proving their power every day to greatly improve industrial manufacturing and the team experience.

Like ADF Group, every company must seize this opportunity for productivity and competitiveness. Transforming an industry and directing it towards manufacturing in virtual reality becomes a “must have” in the era of Industry 5.0

To make the most of the potential of virtual reality for industrial production, don’t delay in getting your equipment and support.